USB Pogo Pins 3 Positions

- Overview

- Inquiry

- Related Products

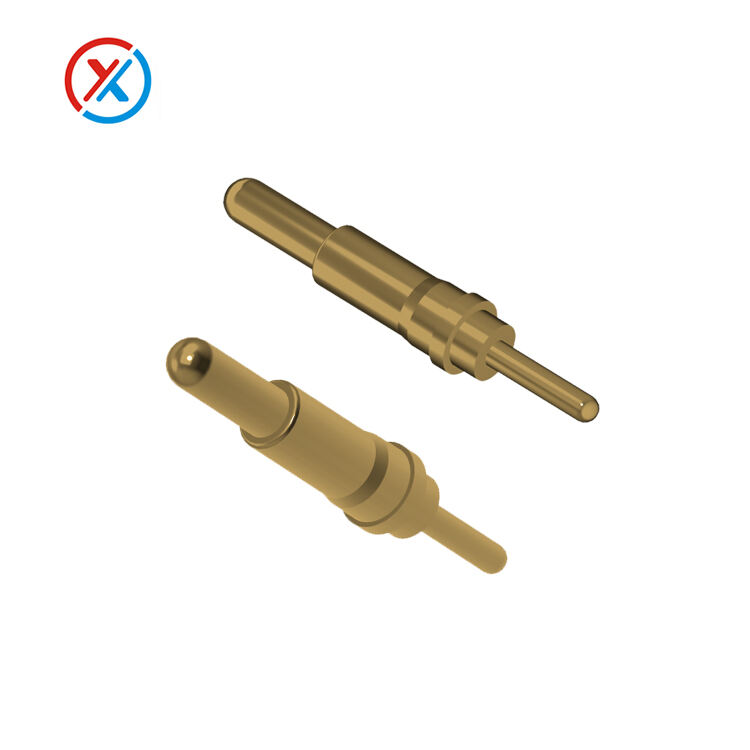

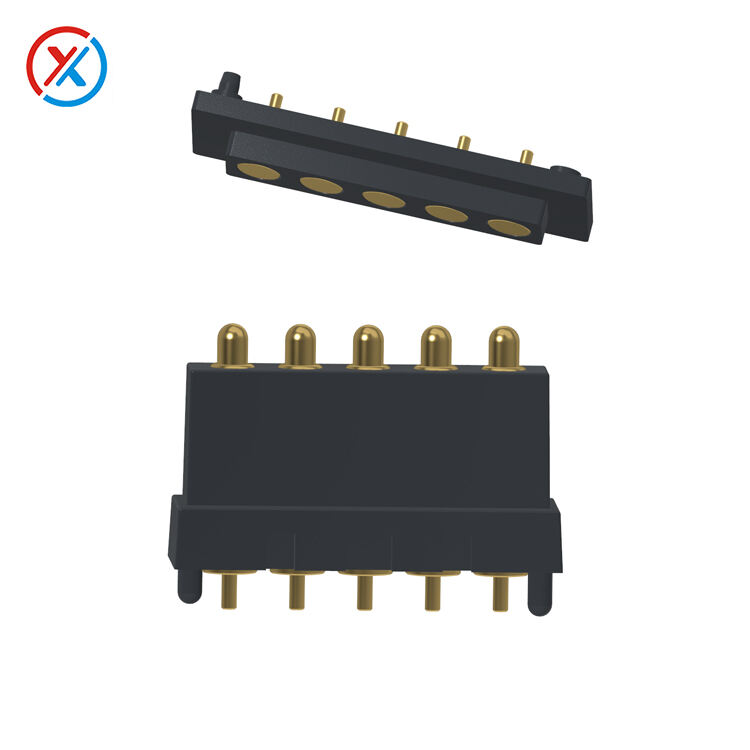

1、USB Pogo Pins 3 Positions

This product features a 4.5mm spacing between its pogo pins, with a maximum single-pin contact resistance of only 50 milliohms. This means low resistance to current flow, ensuring smooth current transmission without slowdowns or overheating due to poor contact points. Coupled with a DC 12V rated voltage and a maximum current of 3A, and a 10,000-cycle lifespan test, it maintains stable contact after 10,000 plug-in and unplug cycles, without becoming loose or sticking. This makes it perfect for devices that frequently require plugging and unplugging.

Note: This product is a custom-made product made by the customer and cannot be purchased directly. If you need to purchase a bulk order, you will need to open a new mold.

| Magnetic connector male-female connector heads | |

| ITEM | DATA #1 |

| Metallic materials | Brass C6801 |

| Contact force | 60g+20g at 1.5mm working stroke |

| Magnet | N52 |

| Rated current | 3.0 A |

| Contact resistance of spring pin | 50 milliohm Max. |

| Rated voltage | DC 12V |

| Mechanical life | 100,00cycle Min |

| 0peration Temperature | -25℃ to +80℃ |

| Salt Spray | 24H |

| Housing | Halogen-free lead-free insulating plastic |

| Material and coating conform to ROHS and REACH standards | |

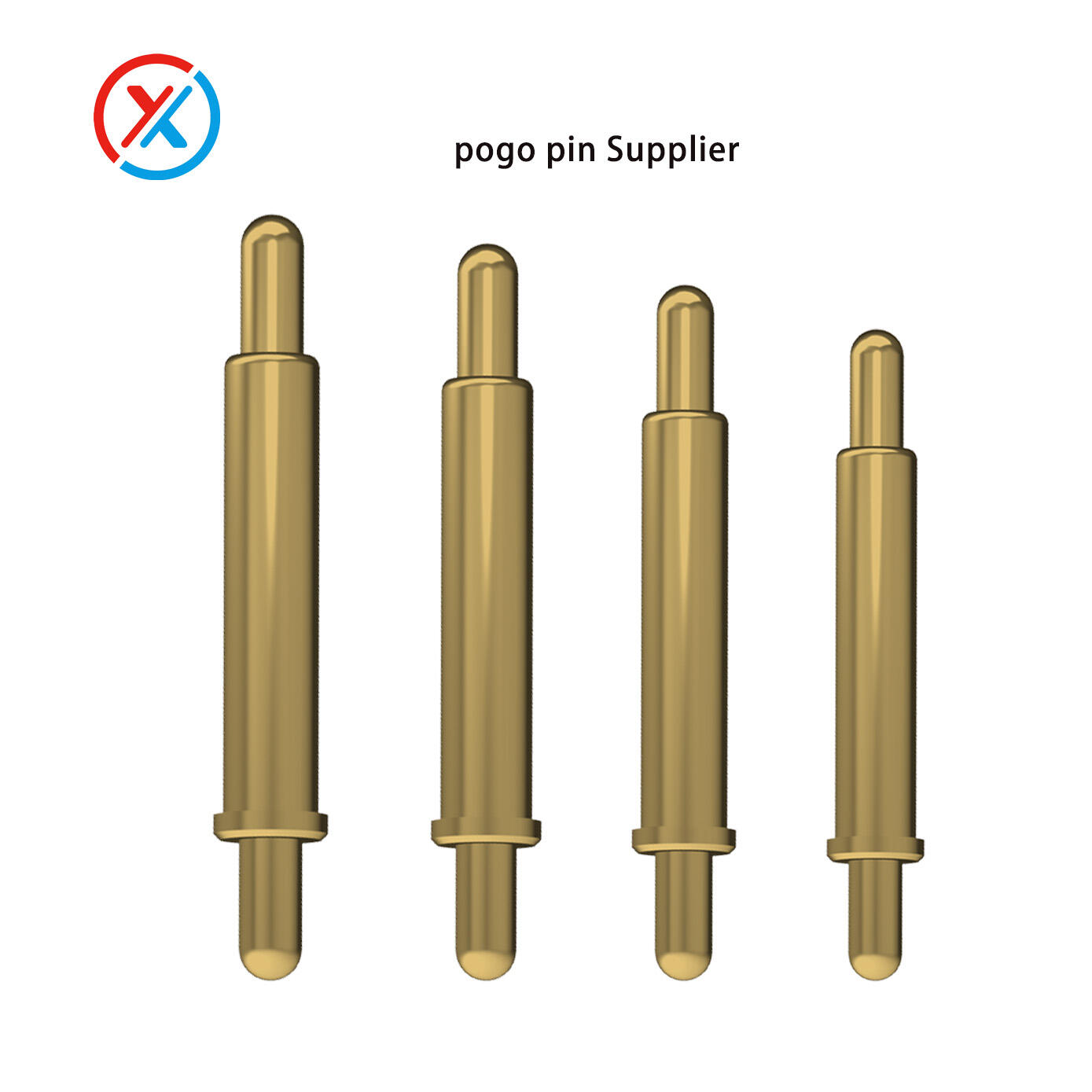

2、Pogo pin magnetic connector scheme can be customized according to your requirements.

1. Shape and structure: round, square, long strip, runway, etc.

2. Wire materials: PVC, TPE, silica gel, etc.

3. Wire shape: round wire, braided wire, flat wire, etc.

4. Waterproof grade: up to IP68.

5. Suction: 150g-3000g.

6. Rated voltage / current: ≤ 120V, ≤ 40A.

7. Connection method: 90 °, 180 °or other angle.

8. Replacement ability: Ihammer O adapter, USB2.0/3.0, HDMI, RJ45, D-SUB, pin busbar, DC Jack, etc.

9. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

10. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

3、How to choose a supplier

1. Product Quality

It is recommended to purchase samples for actual testing, such as plugging and unplugging them 10,000 times, to check for magnetic stability and pin looseness. Also, pay attention to whether the manufacturer uses gold-plated or corrosion-resistant materials in their raw materials.

2. R&D and Customization Capabilities

Choose a supplier with an R&D team that can develop designs tailored to your current, voltage, waterproofing requirements, and other requirements, and support customized customization.

3. Evaluate Delivery Time and Supply Stability

A reliable supplier should not only deliver on time but also maintain stable production even when orders suddenly increase. Be sure to understand the factory's size and inventory situation.

5. Focus on After-Sales Service and Customer Service

The supplier's responsiveness is crucial. A good supplier will actively cooperate within the warranty period and, when necessary, send personnel to assist in analyzing the issue and providing improvement solutions. This is crucial for maintaining device stability.

6. Industry Reputation and Experience

Experienced suppliers often have a better understanding of various application environments, such as automotive, medical, and robotics, which require different structures and materials.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE