What Are the Thermal Benefits of High Current Pogo Pin

In today's rapidly evolving electronics industry, managing thermal performance while maintaining reliable electrical connections has become a critical design consideration. The high current pogo pin represents a breakthrough solution that addresses both electrical conductivity and thermal management challenges in modern electronic systems. These advanced connector pins offer superior performance characteristics that make them indispensable for applications requiring robust current handling capabilities while minimizing thermal stress on sensitive components.

Understanding the thermal benefits of high current pogo pins requires examining their unique design characteristics and material properties. Unlike traditional connectors that may struggle with heat dissipation under heavy electrical loads, these specialized pins are engineered to handle substantial current flows while maintaining optimal operating temperatures. The thermal advantages extend beyond basic heat management to encompass improved system reliability, extended component lifespan, and enhanced overall performance in demanding applications.

Advanced Material Engineering for Superior Thermal Performance

Copper Alloy Construction Benefits

The foundation of exceptional thermal performance in high current pogo pins lies in their advanced copper alloy construction. These precision-engineered materials offer thermal conductivity rates significantly higher than standard connector materials, typically ranging from 200 to 400 watts per meter-kelvin. This superior conductivity enables rapid heat transfer away from connection points, preventing dangerous temperature buildup that could damage sensitive electronic components or compromise system performance.

The copper alloy formulation used in premium high current pogo pins incorporates specific additives that enhance both electrical and thermal properties. Beryllium copper alloys, for instance, provide exceptional spring characteristics while maintaining excellent thermal conductivity. These materials undergo specialized heat treatment processes that optimize their crystalline structure for maximum thermal efficiency, resulting in connectors that can handle current loads up to 10 amperes or higher while maintaining stable operating temperatures.

Surface Treatment Technologies

Advanced surface treatments play a crucial role in maximizing the thermal benefits of high current pogo pins. Gold plating, commonly applied to contact surfaces, not only provides excellent corrosion resistance but also maintains consistent thermal conductivity over extended operating periods. The gold plating process creates a uniform surface layer that facilitates optimal heat transfer while preventing oxidation that could impede thermal performance.

Specialized plating techniques, including selective nickel underplating and controlled gold thickness application, create multi-layer surface structures that optimize both electrical and thermal characteristics. These engineered surfaces maintain low contact resistance even under thermal cycling conditions, ensuring that heat generation remains minimal at connection interfaces. The result is a connector system that delivers consistent thermal performance across thousands of mating cycles.

Design Architecture Optimizing Heat Dissipation

Spring Mechanism Thermal Benefits

The unique spring-loaded design of high current pogo pin systems contributes significantly to their thermal management capabilities. The spring mechanism maintains consistent contact pressure across varying thermal expansion conditions, ensuring stable electrical connections that minimize resistive heating. This constant pressure compensation prevents the formation of micro-gaps that could increase electrical resistance and generate unwanted heat.

The barrel design of high current pogo pins incorporates thermal mass optimization that aids in heat absorption and distribution. The cylindrical structure provides multiple pathways for thermal conduction, allowing heat generated at the contact point to disperse throughout the connector body and into the surrounding mounting structure. This distributed thermal management approach prevents localized hot spots that could compromise connector reliability or damage adjacent components.

Geometric Optimization for Thermal Flow

Engineering teams designing high current pogo pins employ sophisticated geometric optimization techniques to maximize thermal flow characteristics. The internal cavity design, spring configuration, and contact geometry are carefully balanced to create optimal thermal pathways while maintaining mechanical performance requirements. Computer-aided thermal modeling ensures that heat dissipation occurs efficiently across all operational conditions.

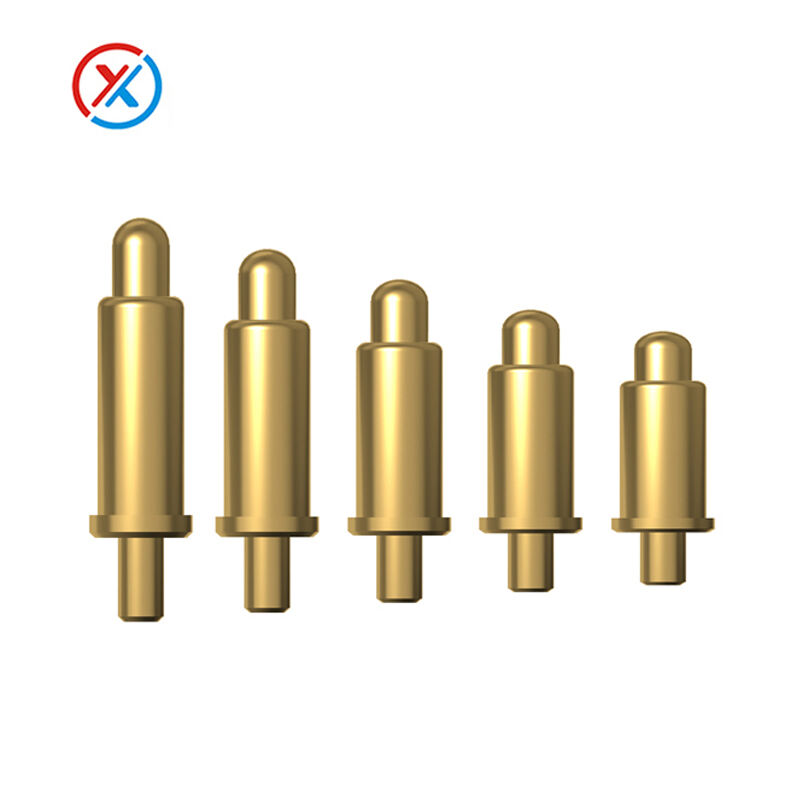

The contact tip geometry of high current pogo pins features optimized surface area calculations that balance electrical contact effectiveness with thermal dissipation requirements. Dome-shaped, crown-shaped, and flat contact configurations each offer specific thermal advantages depending on the application requirements. These geometric variations allow thermal engineers to select connector configurations that best match their system's heat management needs.

Operational Thermal Advantages in Real-World Applications

Reduced System Operating Temperatures

In practical applications, high current pogo pins demonstrate measurable reductions in overall system operating temperatures compared to alternative connector technologies. Test data from automotive electronics applications shows temperature reductions of 15-25 degrees Celsius at connection points when upgrading from standard connectors to high current pogo pin solutions. These temperature reductions translate directly into improved system reliability and extended component lifecycles.

The thermal benefits extend beyond immediate connection points to influence entire circuit board thermal profiles. By eliminating high-resistance connection points that generate excessive heat, high current pogo pins help maintain more uniform temperature distribution across electronic assemblies. This uniform thermal environment reduces thermal stress on sensitive components such as integrated circuits, capacitors, and other heat-sensitive devices.

Enhanced Power Handling Capabilities

The superior thermal management capabilities of high current pogo pins enable electronic systems to handle higher power levels without compromising reliability. Applications in electric vehicle charging systems, industrial automation equipment, and high-performance computing platforms benefit from increased power throughput capabilities while maintaining safe operating temperatures. This enhanced power handling translates into more efficient system designs and improved performance characteristics.

Thermal modeling studies demonstrate that high current pogo pins can handle current densities 40-60% higher than conventional connectors while maintaining equivalent operating temperatures. This capability enables system designers to specify smaller connector arrays for given power requirements, reducing overall system size and weight while improving thermal efficiency.

Long-Term Thermal Stability and Reliability

Thermal Cycling Resistance

High current pogo pins exhibit exceptional resistance to thermal cycling effects that can degrade conventional connector performance over time. The spring-loaded contact mechanism compensates for thermal expansion and contraction cycles, maintaining consistent electrical connections across wide temperature ranges. This thermal cycling resistance ensures stable thermal performance throughout the operational lifetime of electronic systems.

Laboratory testing demonstrates that premium high current pogo pins maintain contact resistance stability within 5% of initial values after 10,000 thermal cycles between -40°C and +125°C. This stability directly correlates to consistent thermal performance, preventing the gradual degradation in heat dissipation capabilities that can occur with other connector technologies over extended operational periods.

Material Stability Under Thermal Stress

The advanced materials used in high current pogo pin construction maintain their thermal properties under extended exposure to elevated temperatures. Copper alloy formulations resist grain growth and property degradation that can occur in high-temperature environments, ensuring consistent thermal conductivity throughout the connector's operational life. Specialized heat treatment processes create stable material structures that resist thermal property changes over time.

Surface treatment systems on high current pogo pins are specifically designed to maintain thermal transfer characteristics under thermal stress conditions. The multi-layer plating structures resist diffusion and degradation effects that could compromise thermal performance, ensuring that heat dissipation capabilities remain consistent across thousands of operating hours at elevated temperatures.

Application-Specific Thermal Benefits

Automotive Electronics Thermal Management

In automotive electronics applications, high current pogo pins provide critical thermal management benefits that enhance system reliability in harsh operating environments. Engine compartment temperatures, thermal cycling from daily temperature variations, and high current demands from modern vehicle electrical systems create challenging thermal conditions that high current pogo pins are specifically designed to address.

Electric vehicle battery management systems particularly benefit from the thermal advantages of high current pogo pins. These connectors enable efficient heat dissipation from high-current charging and discharging operations while maintaining reliable electrical connections under extreme temperature conditions. The thermal benefits contribute to improved battery system efficiency and enhanced safety margins in critical automotive applications.

Industrial Automation Thermal Solutions

Industrial automation equipment operates in demanding thermal environments where high current pogo pins provide essential thermal management capabilities. Manufacturing equipment, robotics systems, and process control applications require reliable electrical connections that can handle substantial current loads while maintaining stable operating temperatures in variable ambient conditions.

The thermal benefits of high current pogo pins in industrial applications extend to reduced maintenance requirements and improved system uptime. By maintaining consistent thermal performance under varying load conditions, these connectors help prevent thermal-related failures that could result in costly production interruptions or equipment damage.

FAQ

How much heat can high current pogo pins dissipate compared to standard connectors

High current pogo pins typically dissipate 40-60% more heat than standard connectors due to their superior material properties and optimized design geometry. The copper alloy construction and spring-loaded contact mechanism create multiple thermal pathways that efficiently transfer heat away from connection points, maintaining lower operating temperatures under equivalent current loads.

What temperature range can high current pogo pins operate in while maintaining thermal performance

Premium high current pogo pins are designed to operate effectively across temperature ranges from -40°C to +125°C while maintaining consistent thermal performance characteristics. The advanced materials and surface treatments resist thermal degradation across these extreme temperature conditions, ensuring reliable heat dissipation throughout the entire operational temperature spectrum.

Do high current pogo pins require special thermal management considerations in system design

While high current pogo pins provide superior thermal performance, optimal results are achieved when integrated into well-designed thermal management systems. Proper mounting substrate selection, adequate thermal pathways to system heat sinks, and appropriate spacing between connectors maximize the thermal benefits and ensure optimal system-level thermal performance.

How do the thermal benefits of high current pogo pins impact overall system reliability

The enhanced thermal performance of high current pogo pins directly contributes to improved system reliability by reducing thermal stress on sensitive electronic components. Lower operating temperatures extend component lifecycles, reduce thermal-related failures, and enable more robust system designs that can handle higher power levels without compromising reliability or performance characteristics.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE