What Are the Advantages of Customized Pogo Pin Solutions

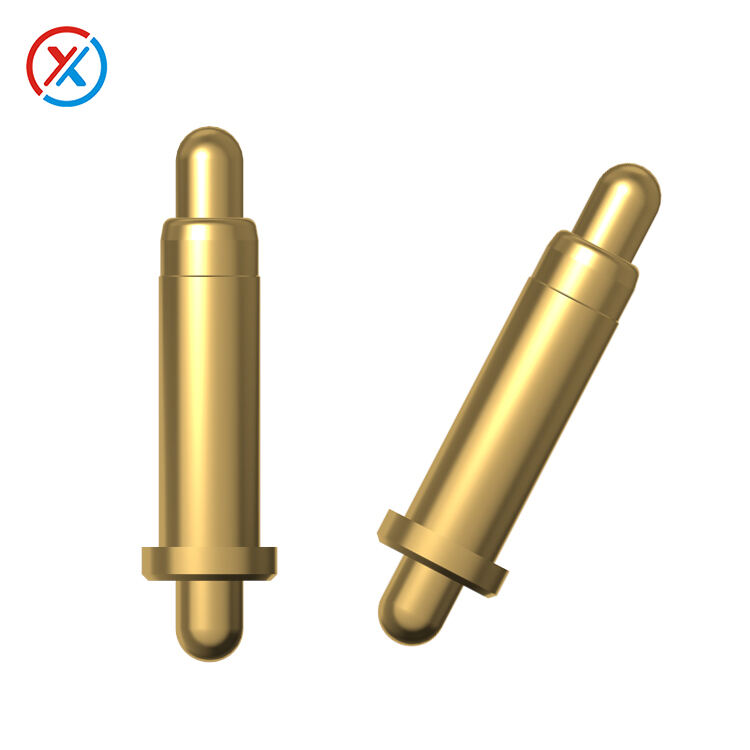

In today's rapidly evolving electronics landscape, manufacturers face increasingly complex connectivity challenges that require specialized solutions. Traditional off-the-shelf components often fall short when dealing with unique form factors, extreme environmental conditions, or specific performance requirements. This is where customized pogo pin solutions emerge as a game-changing technology, offering manufacturers the flexibility to design precise electrical connections tailored to their exact specifications. These specialized spring-loaded connectors have revolutionized how engineers approach temporary electrical connections in compact electronic devices.

The demand for personalized electronic components has surged as devices become smaller, more sophisticated, and designed for specialized applications. Engineers working on medical devices, aerospace systems, consumer electronics, and industrial equipment increasingly rely on custom-engineered pogo pins to achieve reliable electrical connections in challenging environments. These solutions offer superior performance compared to generic alternatives, providing enhanced durability, precise electrical characteristics, and seamless integration with unique device architectures.

Enhanced Performance Through Precision Engineering

Optimized Electrical Characteristics

Customized pogo pin solutions deliver superior electrical performance through precise engineering tailored to specific application requirements. Unlike standard connectors, custom-designed pogo pins can be optimized for exact voltage ratings, current carrying capacity, and resistance specifications. This precision engineering ensures optimal signal integrity, minimal power loss, and consistent electrical performance throughout the connector's operational lifetime. Engineers can specify exact contact force requirements, ensuring reliable connections while preventing damage to delicate circuit boards or components.

The ability to customize electrical characteristics becomes particularly valuable in high-frequency applications where impedance matching and signal integrity are critical. Custom pogo pins can be designed with specific geometric parameters to achieve targeted impedance values, reducing signal reflections and maintaining clean signal transmission. This level of precision is impossible to achieve with off-the-shelf components that are designed for general-purpose applications rather than specialized performance requirements.

Material Selection Advantages

Custom pogo pin manufacturing allows for precise material selection based on specific environmental conditions and performance requirements. Engineers can choose from various contact materials, including gold, silver, palladium, and specialized alloys, each offering distinct advantages for different applications. Gold plating provides excellent corrosion resistance and long-term reliability, while silver contacts offer superior electrical conductivity for high-current applications. The spring mechanism can be crafted from specialized alloys that provide optimal force characteristics and fatigue resistance for the intended application.

Environmental considerations play a crucial role in material selection for customized pogo pin solutions. Applications in harsh environments require materials that resist oxidation, chemical exposure, and extreme temperatures. Custom manufacturing enables the selection of specialized coatings and base materials that provide enhanced protection against specific environmental challenges, ensuring reliable operation in conditions where standard components would fail prematurely.

Mechanical Design Flexibility and Adaptability

Dimensional Customization Benefits

One of the most significant advantages of customized pogo pin solutions lies in their dimensional flexibility, allowing engineers to achieve perfect integration with unique device architectures. Custom pins can be manufactured to exact length specifications, ensuring optimal contact engagement without interference with surrounding components. This precision is particularly valuable in compact electronic devices where space constraints demand precisely sized connectors that maximize available real estate while maintaining reliable electrical connections.

The ability to customize pin diameter, tip geometry, and overall connector configuration enables engineers to optimize mechanical performance for specific applications. Smaller diameter pins can be designed for high-density connector arrays, while larger pins provide enhanced current carrying capacity and mechanical durability. Custom tip geometries, such as pointed, flat, or radius configurations, can be tailored to match specific mating surface requirements, ensuring optimal contact pressure distribution and minimizing wear on both connector and target surfaces.

Force and Travel Specifications

Customized pogo pin solutions offer precise control over contact force and travel characteristics, enabling optimization for specific mating requirements and component sensitivities. Engineers can specify exact force curves that provide reliable electrical contact while preventing damage to delicate circuit boards or flexible circuits. This customization is particularly important in applications involving thin substrates or components with limited structural integrity that cannot withstand excessive mechanical stress.

The ability to customize spring characteristics allows for optimization of connector performance across different operating conditions. Applications requiring frequent mating cycles benefit from springs designed for enhanced fatigue resistance, while temporary test connections may prioritize low insertion force over long-term durability. Custom force specifications also enable engineers to compensate for manufacturing tolerances in mating components, ensuring consistent electrical contact across production variations.

Cost-Effectiveness and Manufacturing Efficiency

Long-Term Value Proposition

While customized pogo pin solutions may require higher initial investment compared to off-the-shelf alternatives, they typically deliver superior long-term value through enhanced reliability and performance. Custom-engineered connectors reduce the need for costly design compromises that often accompany the use of standard components in specialized applications. By eliminating the need for adapter circuits, mechanical modifications, or oversized enclosures to accommodate standard connectors, custom solutions can significantly reduce overall system costs and complexity.

The enhanced reliability of customized pogo pin solutions translates directly to reduced warranty costs, field service requirements, and customer satisfaction issues. Custom-engineered connectors designed for specific environmental conditions and usage patterns typically demonstrate superior longevity compared to general-purpose components operating outside their optimal design parameters. This reliability improvement becomes particularly valuable in applications where connector failure could result in significant downtime or safety concerns.

Supply Chain and Quality Advantages

Working directly with custom pogo pin manufacturers provides greater control over quality standards and supply chain management compared to relying on distributor inventories of standard components. Custom manufacturing relationships enable implementation of specialized quality control procedures, material certifications, and performance testing protocols tailored to specific application requirements. This direct relationship also provides greater flexibility in managing production schedules and inventory requirements based on actual demand patterns rather than distributor stock availability.

Custom manufacturing partnerships often provide access to engineering expertise and design optimization services that can enhance overall product performance beyond the connector itself. Experienced custom manufacturers can provide valuable insights into material selection, geometric optimization, and manufacturing processes that improve reliability while reducing costs. This collaborative approach often leads to innovations that benefit both the specific application and the manufacturer's broader product portfolio.

Application-Specific Design Optimization

Industry-Specific Requirements

Different industries impose unique requirements on electrical connectors that generic solutions cannot adequately address. Medical device applications require biocompatible materials, sterilization compatibility, and precise force control to prevent tissue damage during device insertion. Aerospace applications demand components that withstand extreme temperature cycles, vibration, and altitude variations while maintaining consistent electrical performance. Customized pogo pin solutions can be engineered to meet these specialized requirements while optimizing for other critical factors such as weight, size, and electromagnetic compatibility.

Automotive applications present unique challenges including temperature extremes, chemical exposure, and mechanical vibration that require specialized material selection and geometric design. Custom pogo pins for automotive use can incorporate features such as enhanced corrosion resistance, vibration-resistant spring designs, and contact materials optimized for the specific electrical loads encountered in vehicle systems. This specialization ensures reliable operation throughout the vehicle's operational lifetime while meeting strict automotive quality and safety standards.

Integration with Advanced Technologies

Modern electronic devices increasingly incorporate advanced technologies such as wireless charging, high-speed data transmission, and sensor integration that impose specific requirements on electrical connectors. Customized pogo pin solutions can be engineered to support these technologies through optimized electrical characteristics, specialized shielding, and geometric configurations that minimize interference with sensitive circuits. This capability becomes particularly important as devices become more sophisticated and performance requirements more stringent.

The integration of smart features and diagnostic capabilities into customized pogo pin solutions represents an emerging trend that provides additional value to manufacturers. Custom pins can incorporate features such as integrated sensors for monitoring contact resistance, temperature monitoring capabilities, or smart materials that provide visual indication of connection status. These advanced features enable proactive maintenance and enhanced system diagnostics while maintaining the fundamental reliability and performance advantages of custom-engineered connectors.

FAQ

What factors should be considered when specifying customized pogo pin solutions?

Key specification factors include electrical requirements such as voltage, current, and resistance parameters, mechanical requirements including contact force and travel distance, environmental conditions such as temperature range and chemical exposure, geometric constraints including pin diameter and length, mating frequency and expected operational lifetime, and any special requirements such as biocompatibility or specialized certifications. Working closely with experienced manufacturers helps ensure all critical factors are properly addressed in the custom design process.

How do customized pogo pin solutions compare to standard connectors in terms of lead time and availability?

While customized pogo pin solutions typically require longer initial lead times for design and tooling compared to off-the-shelf components, established manufacturing relationships can provide predictable delivery schedules and dedicated production capacity. Many manufacturers maintain rapid prototyping capabilities that can deliver sample quantities within days, allowing for quick evaluation and design iteration. Once production tooling is established, delivery schedules often become more predictable than relying on distributor inventory of standard components.

What quality assurance measures are typically implemented for custom pogo pin manufacturing?

Comprehensive quality assurance programs for customized pogo pin solutions typically include incoming material inspection and certification, dimensional verification using precision measurement equipment, electrical testing including resistance and current carrying capacity validation, mechanical testing for contact force and spring fatigue, environmental testing when required for specific applications, and statistical process control to ensure consistent production quality. Many manufacturers also provide detailed test reports and certifications for critical applications.

Can existing standard pogo pin designs be modified rather than creating completely custom solutions?

Many manufacturers offer semi-custom options that modify existing standard designs to meet specific requirements while reducing development time and costs. Common modifications include length adjustments, tip geometry changes, alternative plating materials, and force specification adjustments. This approach provides many benefits of full customization while leveraging proven design platforms and manufacturing processes. However, applications with unique requirements may still require fully custom engineering to achieve optimal performance and reliability.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE