What Are the Advantages of Straight-Through Pogo Pin

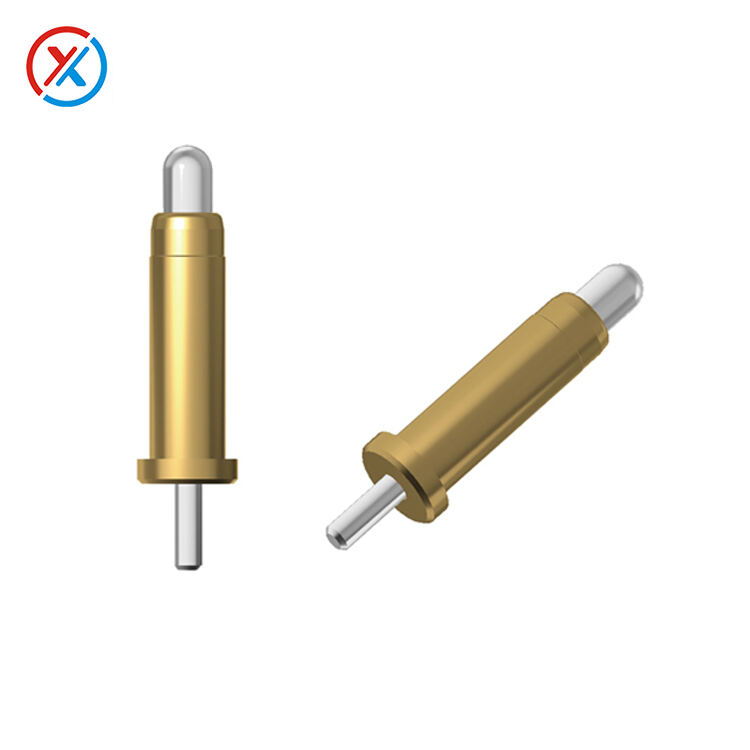

In the rapidly evolving world of electronic connectivity, engineers and manufacturers constantly seek reliable solutions that deliver superior performance while maintaining cost-effectiveness. The straight-through pogo pin has emerged as a game-changing component in modern electronic applications, offering unparalleled advantages over traditional connector designs. These innovative spring-loaded connectors have revolutionized how electronic devices establish temporary or permanent electrical connections, providing enhanced durability, improved signal integrity, and exceptional versatility across diverse industrial applications.

Superior Electrical Performance Characteristics

Enhanced Signal Integrity and Low Resistance

The straight-through pogo pin design delivers exceptional electrical performance through its optimized contact mechanism and precision-engineered construction. Unlike conventional connectors that rely on friction-based connections, these spring-loaded pins maintain consistent electrical contact through controlled pressure application. The gold-plated contact surfaces ensure minimal resistance and superior conductivity, while the straight-through configuration eliminates signal path obstructions that could compromise data transmission quality. This results in cleaner signal propagation with reduced noise interference, making these connectors ideal for high-frequency applications and sensitive electronic circuits.

The inherent design of straight-through pogo pins creates a direct electrical pathway that minimizes voltage drop and power loss. The spring mechanism maintains optimal contact pressure throughout the connector's operational lifespan, ensuring consistent performance even under varying environmental conditions. This reliability becomes particularly crucial in applications where signal integrity directly impacts system functionality, such as test equipment, medical devices, and precision instrumentation where measurement accuracy depends on stable electrical connections.

High-Frequency Performance and EMI Resistance

Modern electronic systems increasingly operate at higher frequencies, demanding connectors capable of maintaining signal integrity across broader bandwidth ranges. Straight-through pogo pins excel in high-frequency applications due to their simplified geometry and minimal parasitic inductance and capacitance. The direct signal path reduces electromagnetic interference susceptibility while providing excellent impedance control characteristics essential for radio frequency and microwave applications.

The controlled impedance properties of these connectors make them particularly valuable in telecommunications, automotive electronics, and aerospace applications where high-speed data transmission is critical. The gold plating not only provides corrosion resistance but also ensures stable electrical characteristics over extended periods, maintaining consistent performance in demanding electromagnetic environments where signal clarity cannot be compromised.

Mechanical Durability and Longevity Benefits

Extended Operational Lifespan

The mechanical design of straight-through pogo pins incorporates high-grade spring steel components that deliver exceptional durability and longevity compared to traditional connector solutions. These connectors can withstand millions of mating cycles while maintaining their electrical and mechanical performance characteristics. The spring mechanism distributes stress evenly across the contact surfaces, preventing premature wear and ensuring consistent contact pressure throughout the connector's operational life.

Quality straight-through pogo pin assemblies undergo rigorous testing to validate their durability under various stress conditions, including temperature cycling, vibration exposure, and repeated mating operations. The robust construction materials and precision manufacturing processes result in connectors that maintain their performance specifications even in harsh industrial environments where traditional connectors might fail prematurely.

Vibration and Shock Resistance

Industrial and automotive applications often subject electronic components to significant mechanical stress through vibration, shock, and thermal cycling. Straight-through pogo pins demonstrate superior resistance to these environmental challenges through their spring-loaded design that accommodates mechanical movement while maintaining electrical continuity. The flexible spring mechanism absorbs vibrations and mechanical disturbances that could otherwise disrupt electrical connections in rigid connector designs.

This mechanical resilience makes straight-through pogo pin connectors particularly valuable in mobile devices, automotive electronics, and industrial equipment where constant movement and vibration are inevitable operational conditions. The ability to maintain stable electrical connections under dynamic mechanical stress significantly reduces system failures and maintenance requirements.

Versatile Application Advantages

Space-Efficient Design Benefits

Modern electronic device design increasingly emphasizes miniaturization and space optimization, creating demand for compact connectivity solutions that deliver maximum performance in minimal footprint applications. Straight-through pogo pins address these requirements through their streamlined design that eliminates bulky connector housings while providing reliable electrical connections. The compact form factor enables designers to achieve higher component density on printed circuit boards while maintaining accessibility for testing and maintenance operations.

The space efficiency of these connectors becomes particularly valuable in portable electronic devices, wearable technology, and Internet of Things applications where every millimeter of available space must be utilized effectively. The straight-through configuration allows for flexible mounting orientations and simplified PCB layout designs that can accommodate various geometric constraints without compromising electrical performance.

Manufacturing and Assembly Efficiency

Production efficiency represents a critical consideration in modern electronics manufacturing, where assembly time and complexity directly impact overall product costs. Straight-through pogo pins simplify the assembly process through their straightforward installation requirements and elimination of complex connector housings or cable assemblies. The self-aligning spring mechanism reduces precision requirements during manufacturing while ensuring reliable connections even with minor positional tolerances.

The simplified assembly process reduces manufacturing costs while improving production throughput and quality consistency. Quality control procedures become more straightforward when using straight-through pogo pins, as visual inspection can easily verify proper installation and contact alignment. This manufacturing efficiency translates into cost savings that can be passed along to end customers while maintaining high-quality standards.

Environmental Performance and Reliability

Temperature Stability and Thermal Management

Electronic systems operating in demanding environments must maintain performance across wide temperature ranges while managing thermal stress that could affect connector reliability. Straight-through pogo pins demonstrate excellent temperature stability through their material selection and design optimization that accommodates thermal expansion and contraction without compromising electrical connections. The spring mechanism provides consistent contact pressure across temperature variations, ensuring stable electrical performance in both high and low temperature applications.

The thermal conductivity properties of gold-plated straight-through pogo pins also contribute to effective heat dissipation in power applications where thermal management becomes critical for system reliability. The direct metal-to-metal contact path facilitates efficient heat transfer while maintaining low electrical resistance, making these connectors suitable for power delivery applications in compact electronic assemblies.

Corrosion Resistance and Environmental Protection

Harsh environmental conditions including humidity, salt spray, and chemical exposure can rapidly degrade conventional connector performance, leading to increased maintenance requirements and system failures. Straight-through pogo pins incorporate gold plating and specialized surface treatments that provide exceptional corrosion resistance and environmental protection. The noble metal contact surfaces resist oxidation and chemical attack while maintaining stable electrical characteristics over extended exposure periods.

The environmental resilience of these connectors makes them particularly valuable in marine applications, outdoor equipment, and industrial processes where exposure to corrosive substances is unavoidable. The combination of material selection and surface treatments ensures long-term reliability without requiring frequent maintenance or replacement, reducing total cost of ownership for critical electronic systems.

Cost-Effectiveness and Economic Benefits

Reduced Maintenance Requirements

The inherent reliability and durability of straight-through pogo pins translate into significant maintenance cost reductions over the connector's operational lifespan. Unlike traditional connectors that may require periodic cleaning, retightening, or replacement due to wear and corrosion, these spring-loaded connectors maintain their performance characteristics with minimal intervention. The self-cleaning action of the spring mechanism helps remove surface contaminants during mating operations, further reducing maintenance requirements.

The reduced maintenance burden becomes particularly valuable in applications where connector access is difficult or where system downtime results in significant operational costs. Remote monitoring equipment, aerospace systems, and industrial automation applications benefit substantially from the reliability advantages of straight-through pogo pins that minimize unexpected failures and scheduled maintenance interventions.

Total Cost of Ownership Advantages

While the initial cost of high-quality straight-through pogo pins may exceed that of basic connector alternatives, the total cost of ownership analysis typically demonstrates significant economic advantages over the system's operational lifetime. The extended lifespan, reduced maintenance requirements, and improved reliability combine to create substantial cost savings that offset the initial investment premium. These economic benefits become more pronounced in high-volume applications where connector reliability directly impacts production efficiency.

The economic advantages extend beyond direct cost savings to include improved system reliability, reduced warranty claims, and enhanced customer satisfaction. The consistent performance characteristics of straight-through pogo pins contribute to overall product quality improvements that can justify premium pricing strategies and strengthen competitive positioning in demanding market segments.

FAQ

What makes straight-through pogo pins more reliable than traditional connectors

Straight-through pogo pins offer superior reliability through their spring-loaded contact mechanism that maintains consistent electrical connections even under vibration, thermal cycling, and mechanical stress. The gold-plated contact surfaces resist corrosion and oxidation while the simplified design eliminates many potential failure points found in complex connector assemblies. The self-cleaning action during mating cycles helps maintain optimal contact conditions throughout the connector's operational life.

How do straight-through pogo pins perform in high-frequency applications

These connectors excel in high-frequency applications due to their direct signal path that minimizes parasitic inductance and capacitance. The straight-through geometry reduces signal reflections and electromagnetic interference while providing controlled impedance characteristics essential for maintaining signal integrity in radio frequency and high-speed digital applications. The minimal signal path length and optimized contact design contribute to excellent bandwidth performance.

What environmental conditions can straight-through pogo pins withstand

High-quality straight-through pogo pins can operate effectively across wide temperature ranges typically from -40°C to +125°C while maintaining electrical performance. The gold plating provides excellent corrosion resistance in humid, salt spray, and chemically aggressive environments. The robust mechanical design withstands vibration, shock, and thermal cycling that would compromise traditional connector reliability in demanding industrial and automotive applications.

How do straight-through pogo pins reduce overall system costs

These connectors reduce total system costs through multiple mechanisms including extended operational lifespan, minimal maintenance requirements, simplified assembly processes, and improved reliability that reduces warranty claims and system failures. The space-efficient design enables higher component density and simplified PCB layouts that reduce manufacturing costs. The consistent performance characteristics also minimize quality control issues and rework requirements during production.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE