Can Female Pogo Pin Connectors Improve Mating Accuracy

Enhancing Electronic Connection Precision Through Advanced Contact Technology

In the rapidly evolving world of electronic device manufacturing, the demand for reliable and precise connection solutions continues to grow. Female pogo pin connectors have emerged as a groundbreaking solution, revolutionizing the way devices interface with one another. These innovative connectors combine sophisticated engineering with practical functionality, offering unprecedented levels of mating accuracy and connection reliability.

The integration of female pogo pin connectors in modern electronic designs represents a significant leap forward in addressing the persistent challenges of maintaining stable electrical connections. As devices become increasingly compact and complex, the role of these specialized connectors becomes more crucial in ensuring consistent performance and durability.

Understanding Female Pogo Pin Connector Technology

Core Components and Design Features

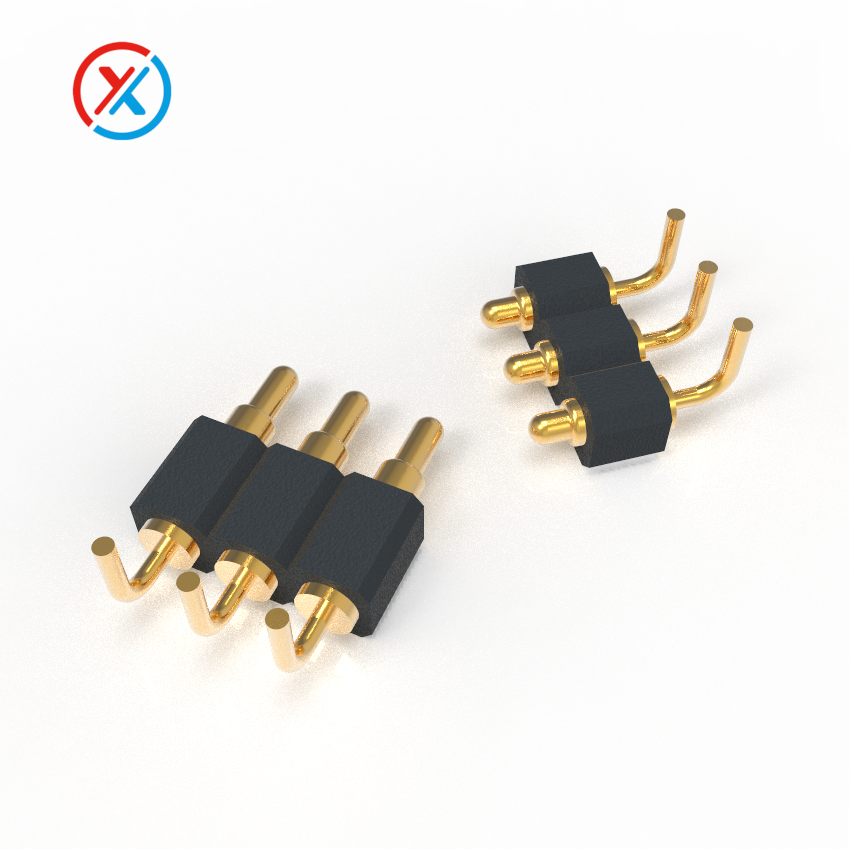

Female pogo pin connectors consist of precisely engineered receptacles designed to accept male pogo pins. The design incorporates advanced spring-loaded mechanisms that ensure optimal contact pressure and alignment. The female housing typically features gold-plated contact surfaces that enhance conductivity and resist corrosion, while the carefully calculated internal dimensions guarantee smooth mating operations.

The socket design often includes guide features that facilitate proper alignment during the mating process. These structural elements work in conjunction with the spring mechanism to create a self-aligning effect, significantly reducing the risk of connection failures and pin damage.

Material Innovation and Manufacturing Excellence

The development of female pogo pin connectors involves selecting high-performance materials that balance durability with electrical efficiency. Advanced alloys and plating technologies ensure excellent conductivity while maintaining mechanical strength. The manufacturing process employs precision engineering techniques to maintain tight tolerances, essential for achieving superior mating accuracy.

Quality control measures in the production of these connectors involve rigorous testing protocols, including dimensional verification, durability assessments, and electrical performance validation. This comprehensive approach to manufacturing ensures each connector meets the exacting standards required for reliable operation.

Benefits of Implementing Female Pogo Pin Solutions

Enhanced Connection Reliability

Female pogo pin connectors offer exceptional connection stability through their unique design characteristics. The spring-loaded mechanism maintains consistent contact pressure throughout the connection lifecycle, even in environments subject to vibration or thermal cycling. This reliability translates to fewer connection failures and reduced maintenance requirements in deployed applications.

The self-aligning properties of female pogo pin connectors contribute significantly to their reliability advantage. Even when initial alignment is less than perfect, the design features guide the pins into proper position, preventing bent pins and ensuring consistent electrical contact.

Improved Manufacturing Efficiency

The implementation of female pogo pin connectors in production processes can lead to substantial improvements in manufacturing efficiency. The robust design and forgiving nature of these connectors reduce the time required for assembly and minimize the risk of connection errors. This translates to higher production throughput and lower rejection rates.

Additionally, the durability of female pogo pin connectors extends their operational lifespan, reducing the frequency of replacement and associated maintenance costs. This longevity makes them particularly valuable in high-cycle applications where connector reliability is paramount.

Applications and Integration Considerations

Industry-Specific Implementation Strategies

Different industries require specific approaches to implementing female pogo pin connectors. In consumer electronics, the focus often lies on miniaturization and high-cycle durability. Medical device applications demand strict attention to biocompatibility and sterilization capabilities. Industrial applications typically prioritize robustness and resistance to harsh environmental conditions.

Each application environment presents unique challenges that must be addressed through careful connector selection and integration planning. Factors such as operating temperature ranges, exposure to chemicals, and mechanical stress must be considered when specifying female pogo pin connector solutions.

Design Optimization Techniques

Successful integration of female pogo pin connectors requires thoughtful consideration of the overall system design. Factors such as board layout, mechanical support structures, and assembly procedures must be optimized to maximize the benefits of these connectors. Engineers must also consider electrical requirements, including current capacity, signal integrity, and EMI shielding needs.

The design process should incorporate adequate clearances and alignment features to ensure reliable mating while maintaining the compact form factor advantages offered by female pogo pin connectors. Proper documentation of design specifications and assembly procedures helps maintain consistency in production.

Future Trends and Developments

Emerging Technologies and Innovations

The field of female pogo pin connector technology continues to evolve, with new developments focusing on enhanced performance characteristics. Innovations in materials science are enabling the creation of connectors with improved electrical properties and greater resistance to environmental factors. Advanced manufacturing techniques are pushing the boundaries of miniaturization while maintaining reliable connection integrity.

Research into smart connector technologies incorporating sensors and diagnostic capabilities represents an exciting frontier in the evolution of female pogo pin connectors. These developments promise to enable real-time monitoring of connection quality and predictive maintenance capabilities.

Market Dynamics and Industry Impact

The growing adoption of female pogo pin connectors across various industries is driving continued investment in research and development. Market trends indicate increasing demand for high-density, high-performance connector solutions, particularly in emerging technologies such as wearable devices and IoT applications.

As manufacturing processes become more automated, the role of reliable, self-aligning connectors becomes increasingly critical. Female pogo pin connectors are well-positioned to meet these evolving needs, supporting the trend toward smart manufacturing and Industry 4.0 initiatives.

Frequently Asked Questions

What makes female pogo pin connectors more accurate than traditional connectors?

Female pogo pin connectors achieve superior mating accuracy through their spring-loaded design, self-aligning features, and precision-engineered housing. The combination of these elements ensures consistent contact pressure and automatic correction of minor misalignments during the mating process.

How long do female pogo pin connectors typically last?

The lifespan of female pogo pin connectors varies depending on usage conditions, but they are typically rated for tens of thousands of mating cycles. With proper implementation and maintenance, these connectors can maintain reliable performance for extended periods, often exceeding traditional connector solutions.

Are female pogo pin connectors suitable for high-speed data transmission?

Yes, female pogo pin connectors can be designed to support high-speed data transmission. Advanced materials and careful impedance control in the connector design enable excellent signal integrity performance, making them suitable for various high-speed applications.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE