Why Use Female Pogo Pin Connectors in High-Reliability Systems

Understanding the Role of Spring-Loaded Contacts in Mission-Critical Applications

In the ever-evolving landscape of electronic systems, reliability and performance are paramount considerations for engineers and designers. Female pogo pin connectors have emerged as a game-changing solution for high-reliability systems, offering unique advantages that make them indispensable in mission-critical applications. These sophisticated interconnect solutions combine precision engineering with robust design principles to deliver consistent performance under demanding conditions.

The integration of female pogo pin connectors in modern electronic systems represents a significant advancement in connector technology. Their innovative design incorporates spring-loaded contacts that ensure stable connections while accommodating variations in height, alignment, and surface irregularities. This adaptability makes them particularly valuable in applications where consistent electrical contact is essential for system reliability.

Design Advantages of Female Pogo Pin Technology

Mechanical Resilience and Durability

Female pogo pin connectors excel in environments where mechanical stress is a constant concern. The spring-loaded mechanism absorbs shock and vibration, preventing connection failures that could compromise system integrity. This inherent resilience translates to extended operational lifespans, with many designs rated for tens of thousands of mating cycles.

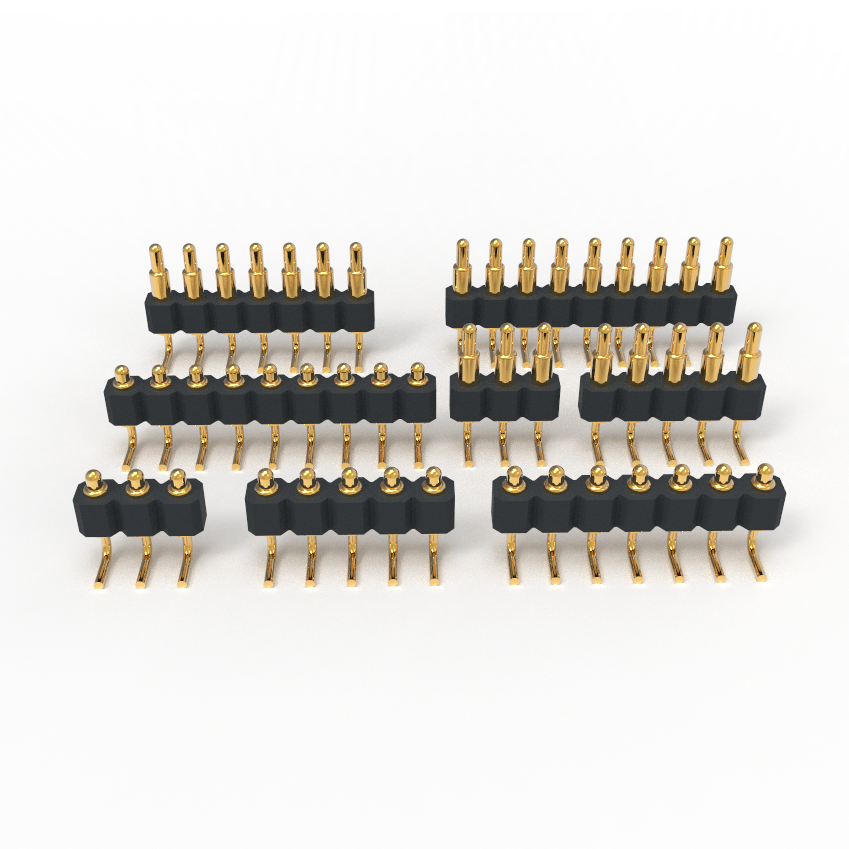

The robust construction of female pogo pin connectors incorporates high-grade materials that resist wear, corrosion, and environmental factors. Gold-plated contacts ensure optimal conductivity while maintaining resistance to oxidation, making these connectors suitable for use in harsh industrial environments and outdoor installations.

Space-Efficient Contact Design

Modern electronic devices demand increasingly compact form factors without sacrificing functionality. Female pogo pin connectors address this challenge through their space-efficient design. The vertical travel mechanism allows for significant reduction in connector footprint compared to traditional pin-and-socket arrangements, enabling higher density connections in limited spaces.

Engineers can leverage this space efficiency to develop more compact products or incorporate additional features within existing form factors. The versatility of female pogo pin connectors makes them particularly valuable in portable devices, medical equipment, and aerospace applications where space optimization is crucial.

Performance Benefits in Critical Systems

Enhanced Signal Integrity

Signal integrity is paramount in high-reliability systems, and female pogo pin connectors excel in maintaining clean signal transmission. The spring-loaded contacts ensure consistent pressure and contact area, minimizing impedance variations and reducing signal degradation. This characteristic is especially important in high-speed data transmission and sensitive measurement applications.

The design of female pogo pin connectors also incorporates features that minimize electromagnetic interference (EMI) and cross-talk between adjacent pins. This attention to signal quality makes them ideal for applications in medical diagnostics, test equipment, and telecommunications infrastructure.

Thermal Management Capabilities

High-reliability systems often operate in environments with significant temperature fluctuations. Female pogo pin connectors demonstrate excellent thermal stability, maintaining consistent performance across a wide temperature range. The spring mechanism compensates for thermal expansion and contraction, preventing connection failures due to temperature-induced stress.

Additionally, the materials used in female pogo pin connectors are selected for their thermal conductivity properties, helping to dissipate heat effectively. This thermal management capability is crucial in power delivery applications and systems with high current requirements.

Implementation Considerations and Best Practices

Design Integration Guidelines

Successful implementation of female pogo pin connectors requires careful consideration of several factors. Engineers must evaluate contact force requirements, travel distance specifications, and environmental conditions to select the appropriate connector configuration. Proper alignment features and mounting provisions should be incorporated into the PCB layout and mechanical design.

Protection against contamination and mechanical damage should be considered during the design phase. This may include incorporating sealed housings, protective covers, or specific mounting orientations to optimize connector performance and longevity.

Manufacturing and Assembly Considerations

The manufacturing process for systems incorporating female pogo pin connectors must maintain tight tolerances to ensure reliable operation. Automated assembly equipment can precisely place and secure these connectors, while quality control measures verify proper installation and functionality.

Regular maintenance protocols should be established to inspect and clean connector surfaces, particularly in applications where environmental contaminants could affect performance. Documentation of installation procedures and maintenance requirements helps ensure consistent system reliability.

Future Trends and Innovations

Advanced Materials and Coatings

The evolution of female pogo pin connectors continues with the development of new materials and surface treatments. Advanced alloys and nano-coatings promise to enhance durability, reduce contact resistance, and improve performance in extreme environments. These innovations will expand the application range of female pogo pin connectors in emerging technologies.

Research into self-cleaning surfaces and smart materials may lead to connectors that require less maintenance while providing improved reliability. Such developments will be particularly valuable in autonomous systems and remote installations where regular maintenance access is limited.

Integration with Smart Systems

As industrial systems become increasingly connected and automated, female pogo pin connectors are evolving to support advanced functionality. Embedded sensors and diagnostic capabilities may soon allow these connectors to monitor their own performance and predict maintenance requirements, contributing to predictive maintenance strategies.

The integration of female pogo pin connectors with Internet of Things (IoT) platforms will enable real-time monitoring of connection quality and system performance. This capability will be particularly valuable in critical infrastructure and manufacturing applications where system uptime is essential.

Frequently Asked Questions

What is the typical lifespan of female pogo pin connectors?

Female pogo pin connectors are typically rated for 20,000 to 100,000 mating cycles, depending on the specific design and application requirements. With proper maintenance and use within specified parameters, these connectors can provide reliable service for many years in high-reliability systems.

How do female pogo pin connectors maintain reliability in vibration-prone environments?

The spring-loaded design of female pogo pin connectors provides natural dampening against vibration and shock. The constant spring force maintains steady contact pressure even during mechanical disturbances, while the floating contact design accommodates minor misalignments that might otherwise cause connection failures.

Are female pogo pin connectors suitable for high-speed data transmission?

Yes, modern female pogo pin connectors are designed to support high-speed data transmission. Advanced designs incorporate impedance matching, EMI shielding, and optimized contact geometry to maintain signal integrity at high frequencies. Many variants are specifically engineered for applications requiring high-bandwidth data transfer.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE