Where Are Large Pogo Pins Commonly Used in Industry

Understanding the Industrial Applications of Spring-Loaded Test Contacts

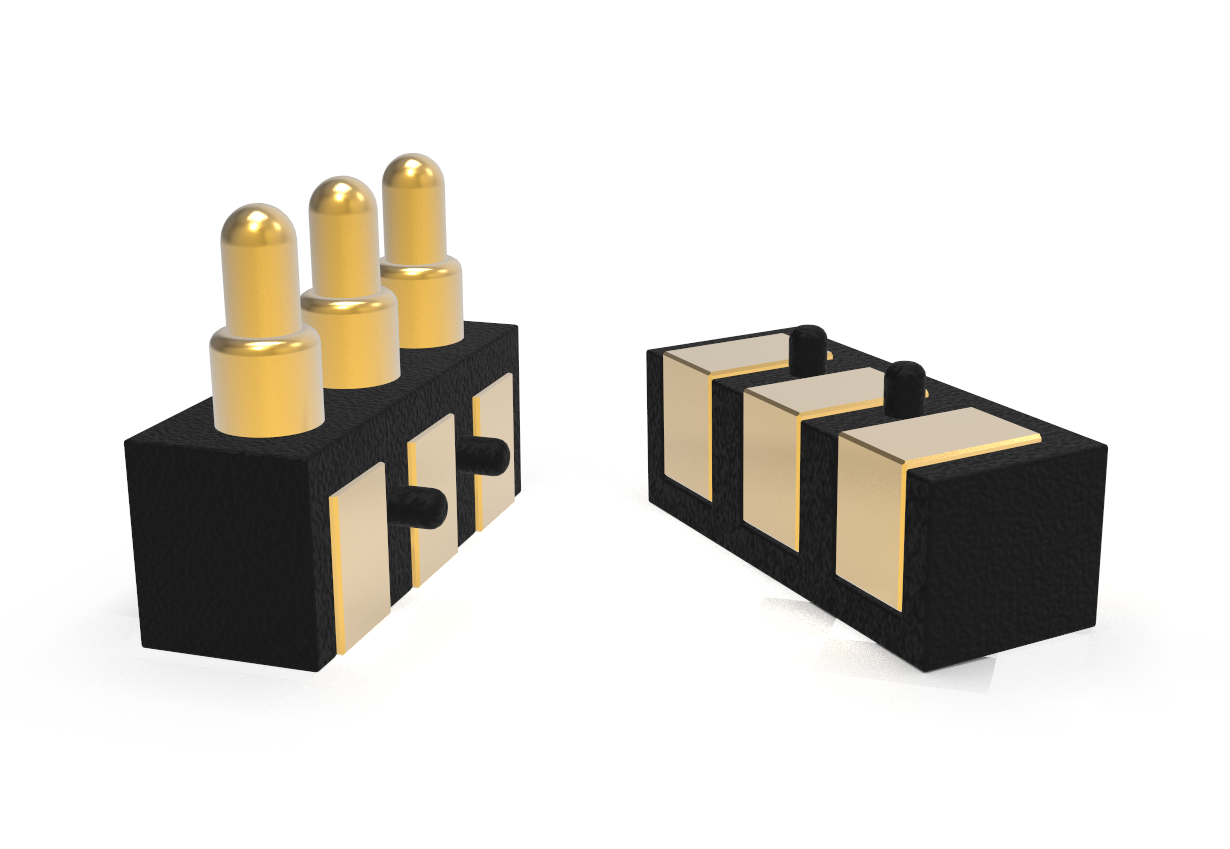

Large pogo pins have become indispensable components in modern industrial applications, serving as reliable electrical connectors across diverse sectors. These spring-loaded contacts, characterized by their robust construction and dependable performance, play a crucial role in ensuring consistent electrical connections in various manufacturing and testing processes. Unlike their smaller counterparts used in consumer electronics, large pogo pins are specifically engineered to handle higher current loads and withstand harsh industrial environments.

Manufacturing and Assembly Applications

Automotive Industry Integration

The automotive sector extensively utilizes large pogo pins in production line testing and assembly operations. These components are essential for testing vehicle control modules, battery management systems, and electronic control units (ECUs). During the manufacturing process, large pogo pins facilitate rapid testing of multiple connection points simultaneously, significantly reducing inspection time while maintaining high accuracy standards.

Modern electric vehicle production particularly benefits from large pogo pins in battery assembly and testing procedures. These connectors enable manufacturers to perform quick yet thorough electrical tests on battery packs, ensuring proper functionality before final assembly. The robust nature of large pogo pins makes them ideal for handling the high current requirements associated with EV battery testing.

Semiconductor Manufacturing Equipment

In semiconductor fabrication, large pogo pins serve as critical components in testing fixtures and handling equipment. They are commonly integrated into wafer probing stations, burn-in test sockets, and automated test equipment. The precision and durability of large pogo pins ensure reliable connections during the intensive testing phases of semiconductor production.

These specialized connectors must maintain consistent contact pressure and electrical conductivity throughout thousands of test cycles. Their spring-loaded design compensates for height variations and ensures stable connections even when dealing with slight misalignments in the testing process.

Testing and Quality Control Applications

Industrial Equipment Testing

Large pogo pins are extensively used in testing fixtures for industrial machinery and equipment. These connectors enable manufacturers to perform comprehensive electrical testing of control panels, power distribution units, and industrial automation systems. The ability to withstand repeated connections and disconnections makes them ideal for production line testing environments.

Quality control departments rely on large pogo pins to conduct thorough testing of finished products before shipment. Their robust construction allows for thousands of test cycles without degradation in performance, ensuring consistent results throughout the quality verification process.

Power Electronics Testing

In the power electronics sector, large pogo pins are crucial for testing high-current devices and systems. They are commonly found in test fixtures for power supplies, inverters, and motor controllers. The superior current-carrying capacity of large pogo pins makes them suitable for applications requiring high-power testing capabilities.

These connectors must maintain stable electrical contact while handling substantial current loads, often in environments where heat dissipation is a critical factor. Their design typically incorporates features that optimize electrical conductivity while managing thermal considerations effectively.

Military and Aerospace Applications

Defense Equipment Manufacturing

The defense industry employs large pogo pins in the production and testing of military electronics and communication systems. These components must meet stringent military specifications for reliability and performance under extreme conditions. From tactical radio systems to missile guidance electronics, large pogo pins ensure dependable connections in critical defense applications.

Military-grade testing equipment often incorporates large pogo pins in custom test fixtures designed for specific defense systems. The robust nature of these connectors makes them suitable for testing equipment that must operate in challenging environmental conditions.

Aerospace Testing Systems

Aerospace manufacturers rely on large pogo pins for testing avionics systems and aircraft electrical components. These connectors are integral to test fixtures used in the production of navigation systems, flight controllers, and communication equipment. The high reliability and precision of large pogo pins make them ideal for aerospace applications where safety and accuracy are paramount.

The aerospace industry's demanding requirements for connector performance have driven innovations in large pogo pin design, resulting in components that offer enhanced durability and electrical characteristics while maintaining precise tolerances.

Medical Device Manufacturing

Medical Equipment Testing

Medical device manufacturers utilize large pogo pins in testing fixtures for various medical equipment, from diagnostic devices to therapeutic systems. These connectors must meet strict regulatory requirements while providing reliable electrical connections for testing complex medical electronics.

The medical industry's need for absolute reliability has led to the development of specialized large pogo pins that can withstand rigorous sterilization processes while maintaining their electrical and mechanical properties. These components are crucial in ensuring the safety and functionality of medical devices before they reach healthcare facilities.

Implantable Device Production

In the production of implantable medical devices, large pogo pins play a vital role in testing and verification processes. These connectors must provide precise electrical connections while meeting stringent cleanliness and biocompatibility requirements. The ability to maintain consistent contact pressure and reliable electrical characteristics is essential in this sensitive application area.

Frequently Asked Questions

What makes large pogo pins suitable for industrial applications?

Large pogo pins are designed with robust materials and construction techniques that enable them to handle higher current loads, withstand frequent cycling, and maintain reliable connections in harsh industrial environments. Their spring-loaded design ensures consistent contact pressure and accommodates varying connection heights.

How long do large pogo pins typically last in industrial settings?

When properly maintained and used within their specified parameters, large pogo pins can typically withstand hundreds of thousands of cycles. Their lifespan depends on factors such as operating environment, maintenance practices, and the specific application requirements they serve.

What maintenance is required for large pogo pins in testing equipment?

Regular maintenance includes cleaning contact surfaces, inspecting for wear or damage, and verifying spring functionality. It's recommended to perform periodic resistance measurements and replace pins that show signs of degraded performance or excessive wear to maintain optimal testing reliability.

Can large pogo pins be customized for specific applications?

Yes, large pogo pins can be customized in terms of size, plating materials, spring force, and current-carrying capacity to meet specific application requirements. Manufacturers often work closely with customers to develop custom solutions for unique testing and connection needs.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE