What Are the Electrical Advantages of Double Head Pogo Pin?

Understanding the Revolutionary Impact of Dual-Headed Spring Contacts

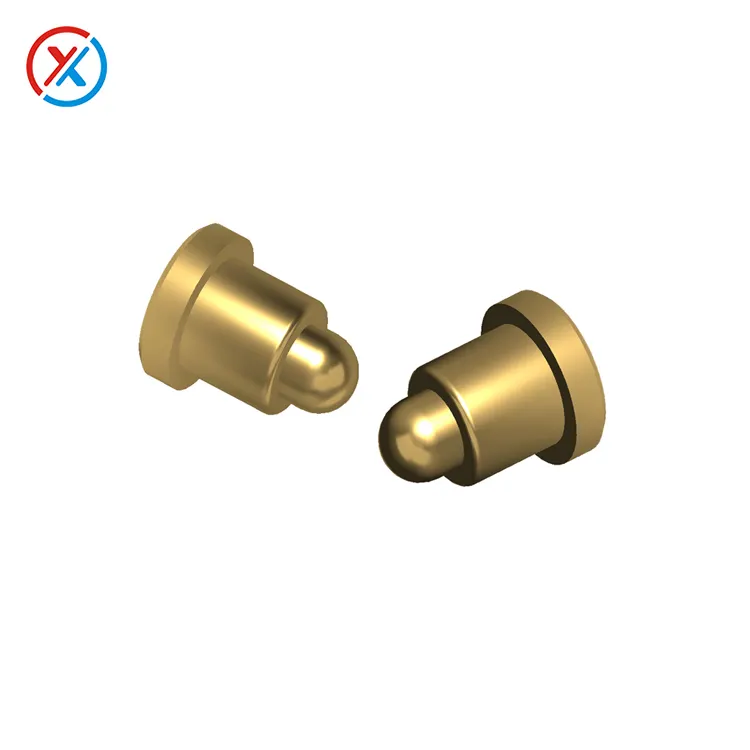

In the ever-evolving world of electronic connectivity, double head pogo pins have emerged as a groundbreaking solution for reliable electrical connections. These innovative components feature contact points on both ends, revolutionizing how we approach circuit board testing, battery connections, and various electronic applications. The unique design of double head pogo pin technology offers superior conductivity, exceptional durability, and remarkable versatility compared to traditional single-headed variants.

The modern electronics industry demands increasingly sophisticated connection solutions that can handle complex testing requirements while maintaining consistent performance. Double head pogo pins address these challenges by providing bidirectional connectivity, enabling signals to flow efficiently between multiple contact points. This advancement has transformed how manufacturers approach product design and testing procedures.

Core Design Elements and Technical Specifications

Structural Components and Materials

The double head pogo pin comprises several precision-engineered components, each contributing to its superior performance. The main body typically consists of brass or phosphor bronze, materials chosen for their excellent conductivity and mechanical properties. The spring element, usually made from high-grade stainless steel, ensures consistent contact pressure and reliable connections throughout thousands of compression cycles.

Both heads feature gold-plated tips, which provide exceptional conductivity while resisting oxidation and wear. This careful material selection ensures optimal electrical performance and extends the component's operational lifespan significantly. The plating thickness typically ranges from 0.1 to 3 microns, depending on the specific application requirements.

Dimensional Considerations and Tolerances

Double head pogo pins are manufactured with precise dimensional tolerances to ensure consistent performance. The standard working length ranges from 3mm to 20mm, with custom sizes available for specific applications. The spring travel distance typically falls between 0.3mm and 2.5mm, providing sufficient compression while maintaining stable contact pressure.

The diameter options usually range from 0.3mm to 3mm, allowing designers to select the most appropriate size for their specific application. These precise dimensions are maintained through advanced manufacturing processes, ensuring reliable operation in various electronic devices.

Electrical Performance Characteristics

Contact Resistance and Conductivity

One of the most significant advantages of double head pogo pins is their exceptional electrical performance. The contact resistance typically measures less than 50 milliohms, ensuring minimal power loss and signal degradation. This low resistance is achieved through the combination of high-quality materials and precision manufacturing techniques.

The gold-plated contacts provide superior conductivity while preventing oxidation, which could otherwise increase resistance over time. This stable electrical performance makes double head pogo pins ideal for applications requiring consistent, reliable connections.

Current Carrying Capacity

Double head pogo pins demonstrate impressive current-carrying capabilities, typically handling between 1A and 3A under normal conditions. This capacity can be customized based on the pin diameter and application requirements. The dual-contact design ensures even current distribution, reducing hot spots and potential failure points.

The spring mechanism maintains consistent contact pressure, which is crucial for stable current flow. This feature makes these components particularly valuable in high-reliability applications where maintaining electrical continuity is critical.

Application-Specific Benefits

Testing and Quality Control Applications

In testing environments, double head pogo pins excel by providing reliable connections for both incoming and outgoing signals. Their ability to maintain consistent contact pressure ensures accurate test results across thousands of cycles. The dual-head design allows for simplified test fixture design, reducing complexity and potential points of failure.

These components are particularly valuable in automated testing systems, where their durability and reliable performance contribute to increased throughput and reduced maintenance requirements. The spring mechanism's consistent force helps prevent damage to delicate components while ensuring reliable electrical contact.

Consumer Electronics Integration

The compact design of double head pogo pins makes them ideal for modern consumer electronics, where space is at a premium. Their reliable performance and durability make them perfect for devices requiring frequent connection and disconnection cycles, such as charging ports and docking stations.

In portable devices, these components help maintain stable connections while accommodating the mechanical stresses of daily use. Their self-aligning properties reduce connection failures and improve user experience in consumer products.

Future Developments and Innovations

Emerging Technologies and Applications

The evolution of double head pogo pin technology continues to advance, with new developments focusing on miniaturization and enhanced performance characteristics. Manufacturers are exploring advanced materials and coating technologies to further improve conductivity and durability while reducing production costs.

Research into smart materials and adaptive spring mechanisms promises to deliver next-generation pogo pins capable of adjusting their properties based on operating conditions. These innovations could revolutionize how we approach electronic connections in future devices.

Industry Trends and Market Impact

The increasing demand for reliable, high-performance electronic connections is driving continued innovation in double head pogo pin design. The market is seeing a trend toward custom solutions that address specific industry challenges, from high-frequency applications to harsh environment operations.

As electronics continue to evolve, the role of double head pogo pins in enabling new technologies and improving existing ones becomes increasingly important. Their adaptability and reliability make them a crucial component in the future of electronic design.

Frequently Asked Questions

What makes double head pogo pins more reliable than traditional connectors?

Double head pogo pins offer superior reliability through their spring-loaded design, gold-plated contacts, and dual-point connection system. This combination ensures consistent electrical contact, even under varying mechanical stress conditions, while the gold plating prevents oxidation and maintains low contact resistance over time.

How long do double head pogo pins typically last?

Under normal operating conditions, double head pogo pins can withstand hundreds of thousands of compression cycles. Their lifespan depends on factors such as usage frequency, environmental conditions, and maintenance practices. With proper care and within specified parameters, they can reliably operate for millions of cycles.

Can double head pogo pins be customized for specific applications?

Yes, double head pogo pins can be customized in terms of size, materials, plating thickness, spring force, and electrical specifications to meet specific application requirements. Manufacturers can adjust these parameters to optimize performance for particular use cases while maintaining the core benefits of the technology.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE